From Concepts to Application: Vacuum Electrical Interfaces Described

In the realm of scientific inquiry and industry practices, upholding a stable setting is essential for best outcomes. This is the moment that vacuum electrical connectors come into play, serving as crucial components that facilitate the seamless transfer of electrical signals and power between the outside and the inside of a vacuum system. These devices are central in a range of areas, including semiconductor production, subatomic physics, and materials science, where regulated environments are required to carry out experiments as well as produce high-quality materials.

Grasping vacuum feedthroughs is fundamental for those looking to engage with vacuum systems as well as to grasp the complexities of sophisticated environments. These small yet vital components must be crafted to endure the rigors of vacuum conditions meanwhile providing reliable electrical connections. By bridging the gap between two environments, these vacuum connectors enable scientists and engineers to discover new possibilities, making them vital resources in modern technology along with scientific research.

Understanding Vacuum Electrified Connectors

Vacuous electrical connectors represent vital components in a range of vacuous setups, enabling the transfer in electrical impulses or power yet preserving the purity in the vacuum environment. Such instruments exist designed to stop the ingress for contaminants emanating the atmosphere into the vacuous enclosure, and this remains essential to protecting delicate studies or operations. Feedthroughs may be used for a variety of applications, including scientific investigations, microchip production, and vacuous wrapping.

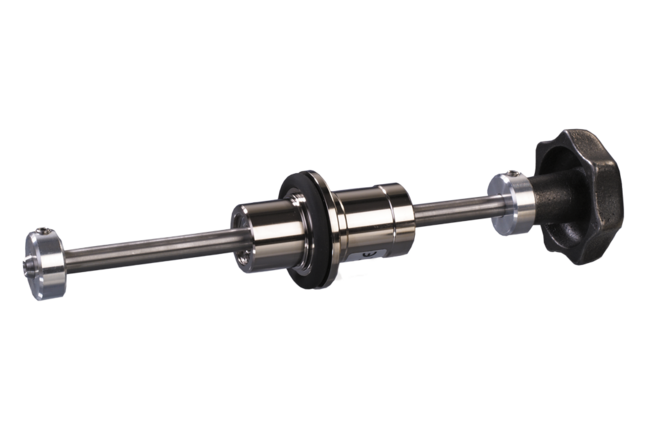

Typically, the construction in a vacuum connector typically involves encapsulating electrified conductors within an isolating material which is capable of tolerating the high vacuum environment. Frequent substances used to serve this purpose comprise ceramics and glass, which offer excellent electrified non-conductivity and elevated tolerance against corrosion. The configuration must guarantee that connector can manage the functional needs, including temperature fluctuations and radiative exposure, while upholding a tight seal against leakage.

In addition to their basic function in offering electrified connectivity, vacuous electrified feedthroughs may also be customized to meet particular application needs. This may encompass changes in the quantity for electrical links, different types of conductors, and combined characteristics like temperature sensors or detecting units. With the advancement of technology advances, the configuration and substances applied for vacuum connectors persist to evolve, enhancing their efficacy and dependability within challenging environments.

Applications of Vacuum Feedthroughs

Vacuum feedthroughs play a essential role in multiple scientific and industrial applications where the quality of a vacuum system must be maintained while allowing for signal connections. One of the key fields utilizing these devices is in the microchip industry, where vacuum chambers are often employed during the fabrication of semiconductors. These connectors facilitate the required electrical signals and power to equipment such as pumps and testing devices without compromising the vacuum environment that are necessary for top-notch manufacturing processes.

In laboratories, particularly within particle accelerators and fusion reactors, vacuum interfaces enable the linking of sensors and sensors to the internal systems. These instruments are important for monitoring parameters such as thermal levels and plasma conditions. By providing a pathway for signal transfer that protects the vacuum environment, these interfaces allow scientists to conduct accurate experiments and gather vital data that informs further investigation and progress.

Additionally, vacuum feedthroughs are significant in the field of vacuum coating technologies. They are used to deliver power to deposition systems that apply thin films on different substrates. This function is vital in the production of optical materials and the development of advanced materials. The ability to retain a vacuum while providing electrical inputs ensures that these processes can be executed with high efficiency and standards, making vacuum connectors an crucial component in state-of-the-art technology applications.

Development Factors and Challenges

When designing vacuum electrical feedthroughs, a primary concerns is making sure that the boundary between the vacuum space and the external atmosphere is preserved without compromising the integrity of the system. Substances used must have favorable electrical properties while also being capable of enduring the vacuum environment. Common materials like ceramics and specific metals are often preferred for their insulating properties and resistance to degrade, but these must be meticulously selected to fit the application’s voltage and thermal requirements.

Another significant issue in the design of vacuum feedthroughs is controlling the thermal expansion and contraction of materials. Different materials expand at varied rates when exposed to temperature changes, which can lead to stress at the junction points. This tension can cause electrical failures or even leaks. As a result, designers must carefully evaluate the thermal characteristics of the materials involved and think about using materials that have compatible thermal expansion coefficients to minimize these issues.

Finally, integrating vacuum feedthroughs into complex systems can introduce complications in terms of space constraints and mechanical design. The feedthrough must not only ensure reliable electrical connections but also integrate within the current architecture of the vacuum chamber or equipment. This may involve compact designs and creative mounting solutions to guarantee that the feedthrough functions effectively without hindering with additional system components. Careful attention must be paid to alignment and sealing methods to promote long-term reliability in the operational environment.